- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- Smart Factory

- Intuitive Software

- Intelligent Processing Cell

- CNC Nesting Machining Center

- Panel Saw

- Edgebanding Machine with Roller Pressure

- High Speed Edgebander with Double V Belt Top Pressure

- Intelligent Processing Edgebanding Machine

- CNC Drilling Machine

- Door Solution

- CNC Machining Center and CNC Router

- Five Axis Machining Center

- Mold Industry

- Furniture packaging paper cutting machine

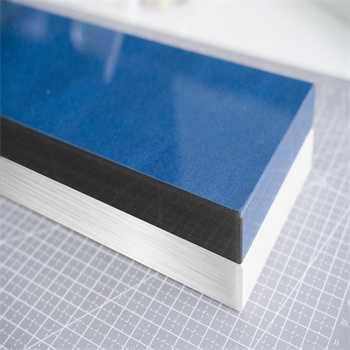

Woodworking Production Board Edge Banding Machine

High quality Woodworking Production Board Edge Banding Machine is offered by China manufacturers Excitech. Buy Woodworking Production Board Edge Banding Machine which is of high quality directly with low price. Double v-belt top pressure → spray release agent →per milling →servo driven multiple wheel tape magazine1→pre melt1→servo driven pressing 1 →servo driven multiple wheel tape magazine2→pre malt2 →servo driven pressing 2 →double rail end trimming→ heavy-duty pneumatic rough trimming→heavy-duty servo fine trimming→ servo high speed corner trimming →heavy-duty servo scraping →off-cut→flat scraping→spray clean agent →electric buffing1→electric buffing2 Servo control unit

Model:EF783GC

Send Inquiry

Woodworking Production Board Edge Banding Machine

High quality Woodworking Production Board Edge Banding Machine is offered by China manufacturers Excitech. Buy Woodworking Production Board Edge Banding Machine which is of high quality directly with low price.

Double v-belt top pressure → spray release agent →per milling →servo driven multiple wheel tape magazine1→pre melt1→servo driven pressing 1 →servo driven multiple wheel tape magazine2→pre malt2 →servo driven pressing 2 →double rail end trimming→ heavy-duty pneumatic rough trimming→heavy-duty servo fine trimming→ servo high speed corner trimming →heavy-duty servo scraping →off-cut→flat scraping→spray clean agent →electric buffing1→electric buffing2

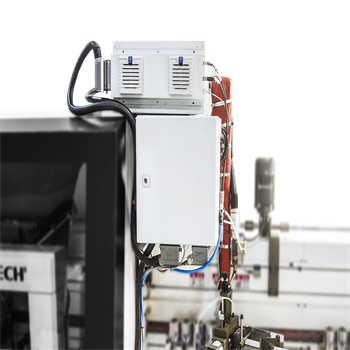

Servo control unit

Accurate adjustment,reduce standby time,increase productivity.

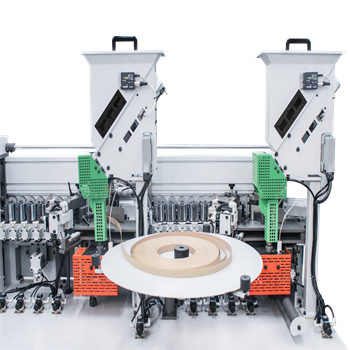

Heavy-duty trimming unit

Sturdy design

Servo tape magazine

Multiple wheel magazine automatically changes edge with servo motor.

The process is both accurate and swift.

4/6/12 tape magazines optional

EF683GIIN functions

Double v-belt top pressure→spray release agent→pre milling→single wheel tape magazine 1→gluing 1→pressing 1→single wheel tape magazine 2 →pre melt 2→pressing2→horizontal end trimming →rough trimming →fine trimming →servo corner trimming→scraping→flat scraping→off-cut →spray clean agent→pneumatic controlled buffing 1 →pneumatic controlled buffing2

Different glue application systems available:

Double glue reservoirs top malt/bottom melt optional (two glue reservoirs to quickly switch between colors and to achieve invisible joint .)

Hot melt device (top pre-melter reduces heating time and increases the quality of edge banding. )

PUR hot melt (for water resistant applications. Optically invisible joints. Perfect finish as a matter of course)

Hot air edge banding technology(available for edges with pvc,abs,pp,pmma.or melamine coating)

Zero glue line,minimum heating time required,water-resistant,saving the trouble of cleaning the glue pots.