- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- Smart Factory

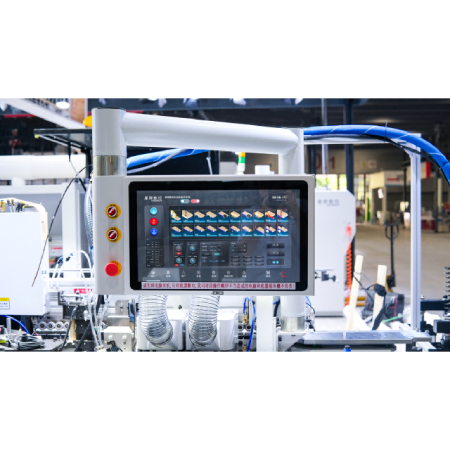

- Intuitive Software

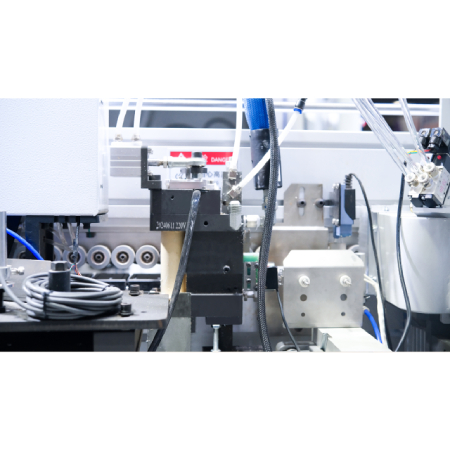

- Intelligent Processing Cell

- CNC Nesting Machining Center

- Panel Saw

- Edgebanding Machine with Roller Pressure

- High Speed Edgebander with Double V Belt Top Pressure

- Intelligent Processing Edgebanding Machine

- CNC Drilling Machine

- Door Solution

- CNC Machining Center and CNC Router

- Five Axis Machining Center

- Mold Industry

- Furniture packaging paper cutting machine

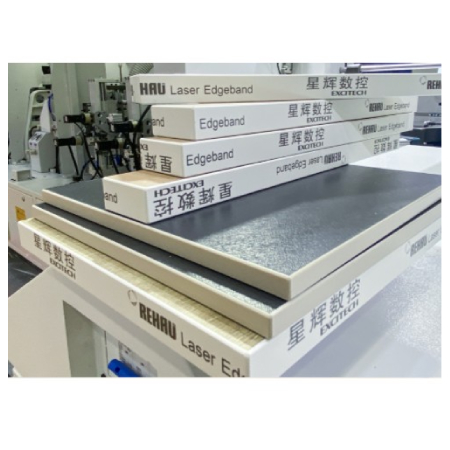

Laser Edgebander Machine

Laser Edgebander Machine for woodworking for Smooth Corner Rounding is an important process in the manufacture of panel furniture. The quality of the edge banding directly affects the quality, price and grade of the product.

Model:EF588GW

Send Inquiry

Laser Edgebander Machine

1.Edgebander Introduction

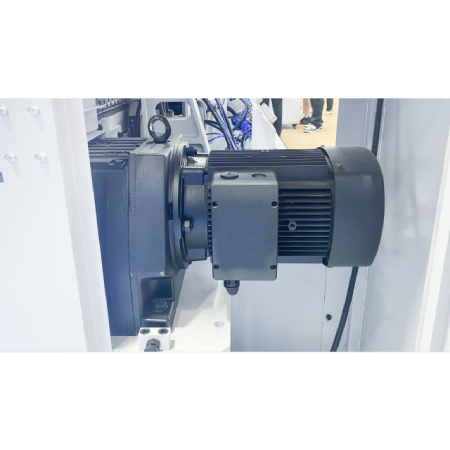

EXCITECH CNC servo end laser edge banding machine EF588GW-LASER

2.Edgebander Parameter (Specification)

|

Series |

Dimension |

Power |

Working Speed |

Panel thickness |

Min Workpiece |

Edge thickness |

Edge Width |

Workpiece Length |

Workpiece Width |

|

LASER-588GW |

7750*1800*970mm |

33.2KW |

16-24m/min |

9-60mm |

60*150mm |

0.4-3mm |

16-65mm |

Min.150mm |

Min.60mm |

|

583GIM |

9870*1800*980 |

27.5kW |

18-24m/min |

10-60mm |

60*150mm |

0.4-3mm |

16-65mm |

Min.150mm |

Min.60mm |

|

583GM |

9720*1800*980 |

26.5kW |

|||||||

|

583GI |

8950*1800*980 |

26kW |

|||||||

|

583G |

8800*1800*980 |

25kW |

|||||||

|

583 |

7040*1800*980 |

16kW |

|||||||

|

582 |

6400*1800*980 |

12kW |

|||||||

|

581 |

5810*1800*980 |

15.5kW |

|||||||

|

580 |

5110*1800*980 |

11kW |

3.Edgebander Feature And Application

Main functions:

Mechanical height limit → plate spacing limit → guide rail guide rule → front spraying → per-milling → preheating lamp → two-color PUR→ laser sealing → servo belt feeding → five-wheel pressing → rough repair → servo fine repair → servo edge scraping → floating flat scraping → single guide rail trimming → heavy four-knife tracking → rear spraying → column-type shifting polishing 1→ column-type shifting polishing 2.

4.Main parameters

|

total power |

29KW |

|

Overall dimensions |

7750 * 970 * 1800 mm |

|

feed speed |

18-24m (the laser is synchronized with the host speed) |

|

minimum size |

40x240mm |

|

Plate length |

≥ 120mm |

|

Sheet width |

≥ 40 mm |

|

Sheet thickness |

9 ~ 25mm |

|

width of edge banding |

12~30mm |

|

Thickness of edge banding tape |

0.4-3mm |

——Various Customers Benefiting from EXCITECH edgebander technology——

5.EF583 Edgebander with Pre Milling and Corner Trimming Qualification

Production Facility

Picture taken at customer's factory

In-house machining facility

Quality control and testing

EF583 edgebander with Pre milling and Corner Trimming in Our Partners’Factories

Honors

|

1 |

Award for

International Registration of Trademark |

|

2 |

China Famous

Brand |

|

3 |

National Top 10

Well-Known CNC Manufacturer |

|

4 |

UL、CE、EAC、CSA 、ISO Certificate and So on... |

6.Deliver,Shipping And Serving

Shipping

The EF583 edgebander with Pre milling and Corner Trimming is packed with anti-rust plastic film for cleaning and damp proofing.

Fasten EF583 edgebander with Pre milling and Corner Trimming on the plywood pallet for safety and against clashing.

Port

Qingdao Port / Tianjin Port / Shanghai / As appointed

Service

■ From your first inquiries about our machine to close the deal to installation to technical support and maintenance, our team will be always with you.

■ Excitech provides 24hr factory support with a team of highly experienced engineers that serve customers and partners around the world , around the clock.

■ No matter whether the machine is used in North America or Africa, we can run diagnostics via dial-in on any of our computer-equipped machines for troubleshooting and correct controller settings to have you running again in a minute.

7.FAQ

1. What are the advantages of this machine?

Answer:The machine is fully functional but at a very economical price.

2. How do you check that your machine is up to shipment standards?

Answer: There are professional,strict quality inspection and commodity inspection in our factory.

3. How long is the machine warranty period?

Answer:EXCITECH offers 12 months warranty for service issue that are not caused by operator's errors. Service and support are available throughout the service life of a machine at fair and reasonable costs after warranty expires.