- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- Smart Factory

- Intuitive Software

- Intelligent Processing Cell

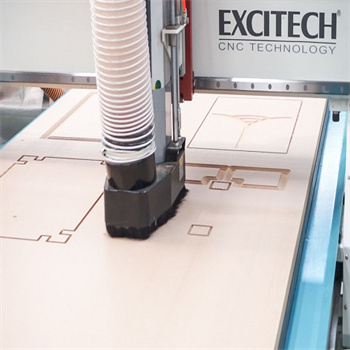

- CNC Nesting Machining Center

- Panel Saw

- Edgebanding Machine with Roller Pressure

- High Speed Edgebander with Double V Belt Top Pressure

- Intelligent Processing Edgebanding Machine

- CNC Drilling Machine

- Door Solution

- CNC Machining Center and CNC Router

- Five Axis Machining Center

- Mold Industry

- Furniture packaging paper cutting machine

Machine Center for Mold and Eps Three Axis Machining

Find a huge selection of Machine Center for Mold and Eps Three Axis Machining from China at Excitech. The machine tool is a traditional standard product of Xinghui, with a solid structure, high efficiency and stability Adopt Japan THK guide rail, maintenance-free self-lubricating The original imported Italian HSD high-speed motorized spindle is adopted, and the maximum spindle speed reaches 24000RPM to ensure the optimization of processing efficiency. Adopt German original imported rack, stable transmission and high precision Adopt German IGUS original imported cable, high flexibility and anti-interference

Model:machinung center for mold and eps

Send Inquiry

Machine Center for Mold and Eps Three Axis Machining

Find a huge selection of Machine Center for Mold and Eps Three Axis Machining from China at Excitech.

l The machine tool is a traditional standard product of Xinghui, with a solid structure, high efficiency and stability

l Adopt Japan THK guide rail, maintenance-free self-lubricating

l The original imported Italian HSD high-speed motorized spindle is adopted, and the maximum spindle speed reaches 24000RPM to ensure the optimization of processing efficiency.

l Adopt German original imported rack, stable transmission and high precision

l Adopt German IGUS original imported cable, high flexibility and anti-interference

|

Series |

SHLS 1525 |

SHLS 2040 |

|

Effective travel range |

1500*2500*800mm |

2000*4000*800mm |

|

Distance from spindle nose to table |

50-850mm |

|

|

Transmission form |

X, Y rack; Z lead screw |

|

|

Idle speed |

≥16000mm/min |

|

|

Speed of work |

≥10000mm/min |

|

|

Spindle power |

9.6KW |

|

|

Spindle speed |

24000r/min |

|

|

Countertop structure |

Reinforced aluminum alloy table top |

|

|

Servo motor |

Yaskawa, Japan |

|

|

Operating system |

Taiwan New Generation |

|

|

Operating Voltage |

AC380V/50HZ |

|

■Free on-site installation and commissioning of new equipment, and professional operation and maintenance training

■Perfect after-sales service system and training mechanism, providing free remote technical guidance and online Q&A

■There are service outlets all over the country, providing 7 days * 24 hours local after-sales service response to ensure the elimination of equipment transportation in a short time

Related questions in line

■Provide professional and systematic training services to the factory, software use, equipment use, maintenance, common fault handling, etc.

The whole machine is guaranteed for one year under normal use, and enjoys lifetime maintenance services

■Revisit or visit regularly to keep abreast of equipment usage and eliminate customer worries

■Provide value-added services such as equipment function optimization, structural change, software upgrade, and spare parts supply

■Provide integrated intelligent production lines and unit combination production such as storage, material cutting, edge sealing, punching, sorting, palletizing, packaging, etc.

Customized service for program planning

Global Presence,Local Reach

Excitech has proven itself quality-wise by its successful presence in over 100 countries worldwide.Supported by a strong and resourceful sales and marketing network as well as technical support teams who are well trained and committed in providing our partners the best possible service,Excitech has gained a global reputation as one of the most reliable and trusted CNC machinery solution pro-

viders.Excitech provides 24hr factory support with a team of highly experienced engineers that serve customers and partners around the world,around the clock.

A Committment to Excellence Excitech,a professional machinery manufacturing

company,was established with the most discriminating customers in mind. Your Needs,Our Driving Force We are committed to making your business a success by providing customized solutions necessary in achieving your goals.The seamless integration of our machineries with industrial automation software and system enhances our partners‘competitive advantages by helping them achieve:

Quality,Service and Customer Centric while Creating Unending Value

-----These are the Fundamentals of EXCITECH