- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- Smart Factory

- Intuitive Software

- Intelligent Processing Cell

- CNC Nesting Machining Center

- Panel Saw

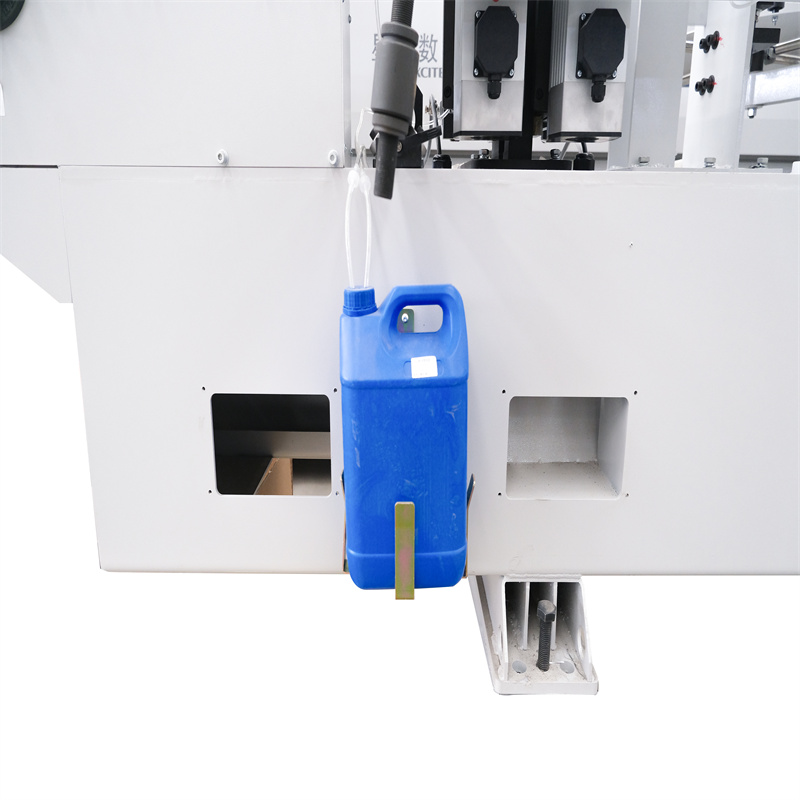

- Edgebanding Machine with Roller Pressure

- High Speed Edgebander with Double V Belt Top Pressure

- Intelligent Processing Edgebanding Machine

- CNC Drilling Machine

- Door Solution

- CNC Machining Center and CNC Router

- Five Axis Machining Center

- Mold Industry

- Furniture packaging paper cutting machine

EF666G High Configuration CNC High-speed Edge Banding Machine

EF666G High configuration CNC high-speed edge banding machine Edge banding work is an important process in the manufacture of panel furniture.

Model:EF 666G

Send Inquiry

EF666G High Configuration CNC High-speed Edge Banding Machine

Main functions:

Pre-spraying → pre-milling → preheating lamp 1→ gluing 1 (without cleaning the glue pot) → single-channel tape feeding 1→ six-wheel pressing 1→ preheating lamp 2→ gluing 2 (with quick sol) → single-channel tape feeding 2→ six-wheel pressing 2→ three-motor trimming → fine repair 1→ fine repair 2→ four-knife tracking → edge scraping 1 (anti-adjustable knife for directional wire blowing) → edge scraping 2.

Functional area

The cylinders are equipped with corresponding cylinders according to the functional areas.

The air source processor filters the moisture in the air through the filter element.

The pressure regulating valve regulates the air pressure.

PLC programmable logic controller controls equipment through digital or analog input and output.

The frequency converter controls the power control equipment of AC motor by changing the frequency mode of motor working power supply, so as to achieve the purpose of energy saving and speed regulation, and also has the function of over-current, over-voltage and overload protection.

Pre-milling motor power: 2.2kw

Quantity: 2

High-quality hard tooth surface conveying motor Power: 5.5kw Quantity: 1 set

Edge banding work is an important process in the manufacture of panel furniture. The quality of the edge banding directly affects the quality, price and grade of the product. By edge banding, it can improve the appearance quality of the furniture, avoid the corners damage and the veneer layer pick up or peel off, and at the same time, it can play the role of waterproofing, close the release of harmful gases and reduce deformation during the transportation and using process. The raw materials used by the panel furniture manufacturers are mainly for particleboard, MDF and other wood-based panels, the selected edge strips are mainly PVC, polyester, melamine and wood strips. The structure of the edge banding machine mainly includes the fuselage, various processing components and control systems. It is mainly used for edge sealing of panel furniture. It is characterized by automation, high efficiency, high precision and aesthetics. It has been widely used in panel furniture manufacturers.