- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

What are the core equipment needed for building a panel furniture factory?

2025-06-17

The basic production process (cutting, edge banding, drilling, laminating/packaging) should be flexibly configured in combination with scale, budget, and product type. Here's a list of equipment and configuration suggestions:

I. Core Essential Equipment

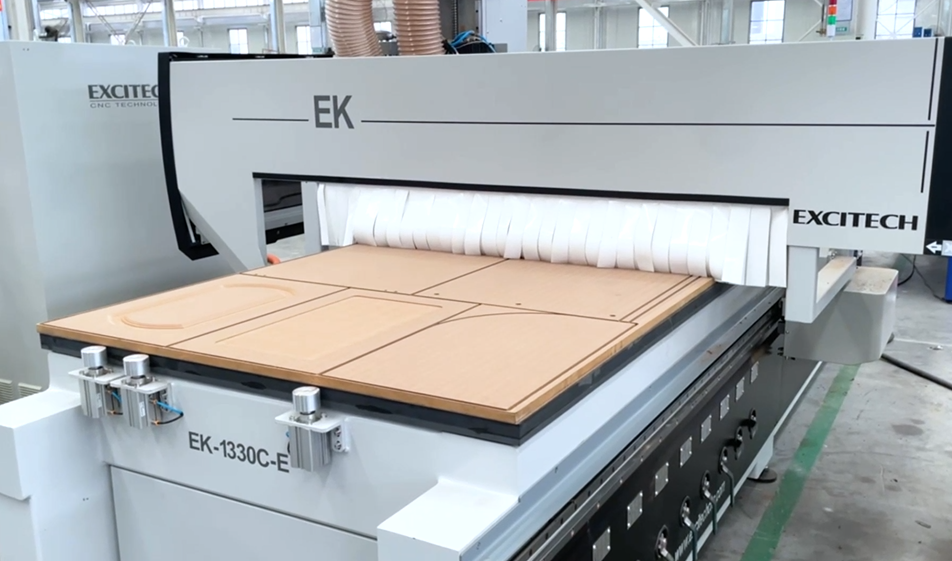

1. CNC Cutting Machine

Function: Panel cutting, vertical drilling, grooving, and irregular processing (radius, engraving).

Selection Suggestions:

Four process cutting machine: Suitable for small factories, for basic cutting and drilling.

Pre-labeling machine + automatic tool change dust-free cutting machine: Dust-free cutting and automatic tool change, meeting various furniture panel production needs, suitable for cabinet and other high-end custom furniture manufacturers.

Panel utilization rate: With optimization software, it can reach 98%+.

2. Fully Automatic Edge Banding Machine

Function: 9 processes (pre-milling, gluing, edge banding, trimming, fine adjustment, polishing, etc.) to ensure edge banding sealing and appearance.

3. Drilling Equipment

Six-sided drilling machine: Completes drilling on all six sides of a panel at once, improving efficiency threefold (12-15 seconds per panel), preferred for medium-sized factories.

4. Vacuum Laminating Machine

Function: PVC film/wood veneer lamination, suitable for door panel thermoforming and irregular part lamination (e.g., cabinet doors).

II. Supplementary Equipment by Product Type

Cabinet production line: Cutting machine + edge banding machine + side drilling machine/six-sided drilling machine (core trio).

Door panel production line:

Cutting machine (with 12-tool automatic tool change model, suitable for complex carving);

Laminating machine + hinge drilling machine (precise hinge hole drilling);

Optional: UV color printer (for patterned door panels), sanding machine (for surface finishing).

III. Practical Points for Factory Construction

1. Power and Space:

Power: Total wiring of 26mm² copper wire, dedicated 10mm² four-core wire for cutting machine, air compressor with 1 cubic meter air storage tank + desiccant.

Workshop size: ≥2.3m×3.8m space for cutting machine; reserve 11m×4m for laminating machine; edge banding machine length 4.5-6m.

2. Software and Maintenance:

Order splitting software must be compatible with the cutting machine system;

Regular maintenance: Clean guide rails/screws of dust, prevent dust in electrical boxes to ensure precision.